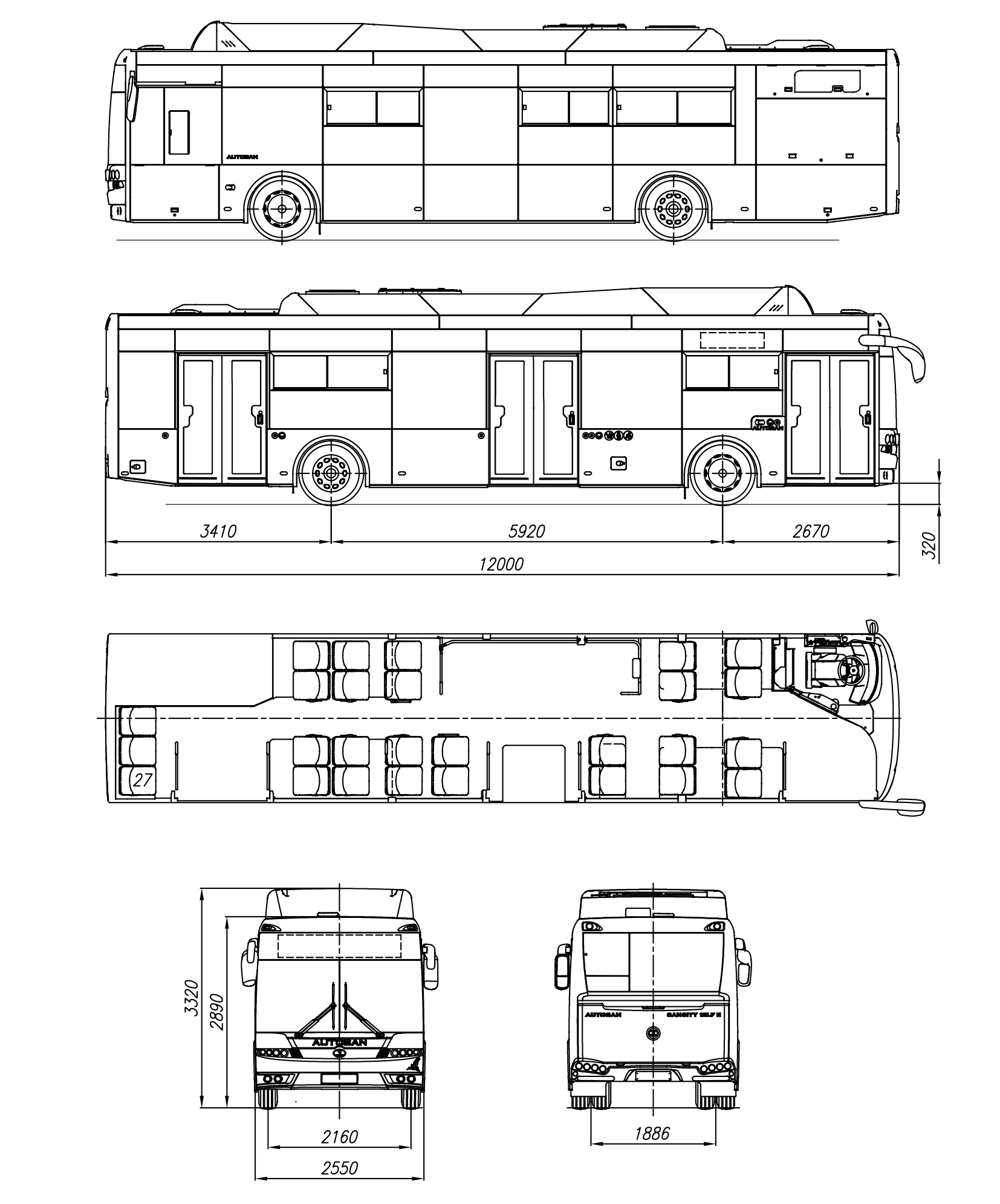

SANCITY 12LFE

SANCITY 12LFE

Zero-emission, fully electric low-floor bus with a length of 12 m, intended for operation in large cities on regular city lines. It moves very quietly, does not emit any fumes, which makes it friendly to city dwellers and the natural environment. It is vibration-free, which significantly improves the comfort of traveling. The installed components (air conditioning, automatic fire extinguishing system in the engine compartment, etc.) ensure the safety and comfort for passengers. Thanks to the use of modern technologies, the bus can travel up to 350 km on a single charge. It is next model of the modular family of buses with the common name SANCITY with alternative drive.

A three-dimensional stainless steel lattice frame integrated with a co-working framework of the body.

Driveline

Engine: TM4, located at the rear of the bus behind the axle, synchronous with power up to 253 kW, with recuperation.

Energy storage

Lithium-ion batteries NMC: BMZ Poland or IMPACT, capacity up to 400 kWh, installed on the roof and rear overhang.

Charging

Plug in, CCS Combo 2 socket, located behind III door on the right side of the vehicle. DC or AC electric charging thanks to the charger installed in the bus.

Axles and wheels

Rear axle: ZF. Front axle: ZF, independent wheel suspension. Driving wheels: tires 275/70 R22,5.

ECAS kneeling system

Brakes

Service brake: pneumatically controlled, disc-type, with EBS/ABS/ASR system. Parking brake: manual with spring actuator, acting on rear wheels.

Electrical system

24V, CAN, KIBES 32 system, batteries: 2 x 225 Ah.

The construction of the body is made of stainless steel rectangular tubes welded together. The outside paneling made of aluminium (sub-window-belt) and GRP panels (front and back walls, roof), bonded to the framework. Side flaps made of aluminium. Heating Hybrid (electric – fuel): water aggregate combined with convectors and heaters, using waste heat from the engine cooling system and power equipment. Ventilation Slidable windows, ventilation unit in the front wall and electric fans (exhaust and blowing) in the roof. Air-conditioning of the passenger space Passenger doors Door system 2-2-2. Double-leaf, opening inwards. Outside mirrors Electrically controlled, heated .

Passenger capacity: seats 22 – 29, total up to 89, total number of places depends on the number of batteries. Passenger seats made of plastic with soft upholstery. The ceiling covered with composite panels and sidewalls with laminated panels. Semi-closed type driver’s cabin with door and FAP MVP console. Big platform opposite middle door for standing passengers and a wheelchair. Manually operated entry platform for wheelchair in the middle door. Handrails powder painted.

– Front axle: ZF, rigid

– Air-conditioning of driver’s cabin

– Driver’s seat electrically heated

– Tilt windows – Glued windshield, made of multi-layer glass, divided vertically

– Outside paneling divided vertically and horizontally

– Plug in, CCS Combo 2 socket located behind I door

– Closed-type driver’s cabin – Central lubrication system

– Tires pressure and temperature monitoring system

– Collision Avoidance System

– Automatic detection and fire-fighting system in engine compartment

– Automatic dipped beam after dark

– Intelligent speed limiter

– Criuse control – Alcohol lock / Immobilizer

– Voice announcement system

– Pantograph charging system

– Battery conditioning system

– LTO batteries – ESC traction control

Marek Ruchlewicz

Commercial director

Woj. Lubelskie, Łodzkie, Małopolskie, Mazowieckie, Podkarpackie, Podlaskie, Świętokrzyskie, Warmińsko-Mazurskie